- Vacuum Soldering

EDA Industries S.p.a.

Established in 1993 in Italy, EDA Industries is experienced engineering company, focused on the production of Burn-In and Test Equipment for the semiconductor industry.

EDA Industries has more than 500 systems installed worldwide in 25 countries, providing a full turn-key solution for Testing, Burn-In and Reliability Test.

Burn-In Test System

By interpreting SiC and GaN mega-trend, EDA designed SocrATE project, putting in place all the skills to develop an exclusive product, in line with the expectations of the AUTOMOTIVE market. SocrATE is a complete Burn-in test system designed specifically to meet the needs of cost-sensitive volume manufacturing of current and next generation SiC, GaN and High Voltage devices. SocrATE offers true site-independent test across a broad range of software-controlled configurations.

Centrotherm international AG

Thermal production solutions and coating technologies are among centrotherm's core competencies.

For more than 70 years we have been developing and implementing production concepts for a constantly growing international customer base. In addition to growth sectors such as the semiconductor and microelectronics industry, as well as photovoltaics, our innovative solutions are also being applied in new future-oriented fields such as fiber or battery production.

Vacuum Soldering

- ●Excellent temperature uniformity up to 0.5%

- ●Independent and separately controlled gas lines

- ●Uptime > 98.5%

- ●Cooling water supply by open water cooling system

- ●Controllable via 19“ touch screen

- ●Remote access for service

- HCOOH

- Hydrogen capability

- Automated operation

c. VACUNITE 300 180

c.VACUNITE 300 and 180 multi-plate vacuum soldering systems are designed for high volume production.

- ●Hydrogen, formic acid or forming gas is applicable.

- ●It reaches temperatures of up to 650°C

- ●The void affected area can be reduced to less than 1%.

- ●The c.VACUNITE 300A offers an excellent solution for automated lines.

c. VACUNITE 24 12 6

c.VACUNITE 24, 12 and 6 are designed for process-specific R&D and pilot-scale production.

- ●Hydrogen, formic acid or forming gas is applicable.

- ●It reaches temperatures of up to 450°C

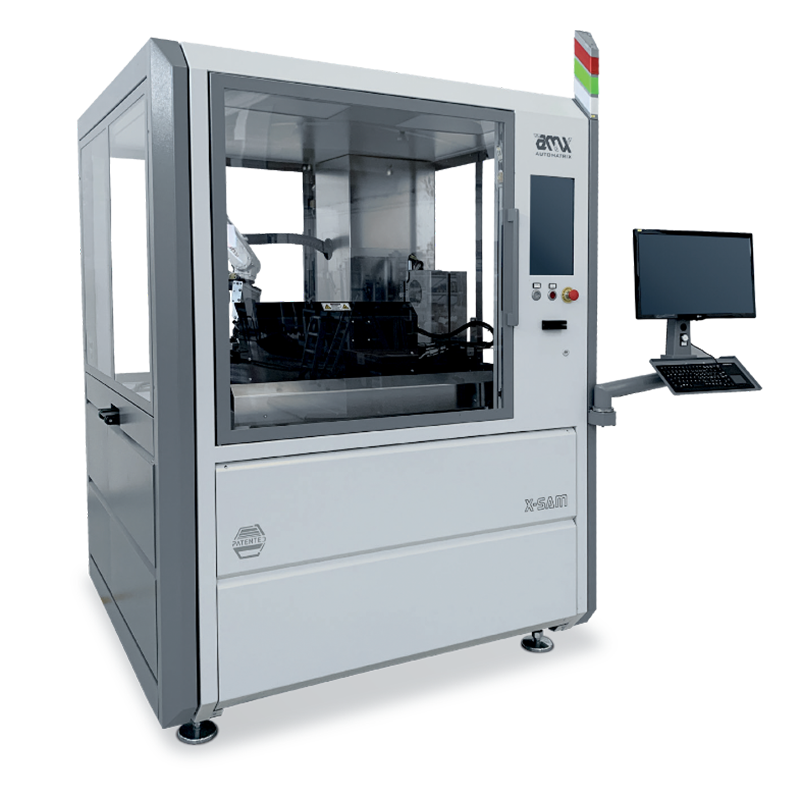

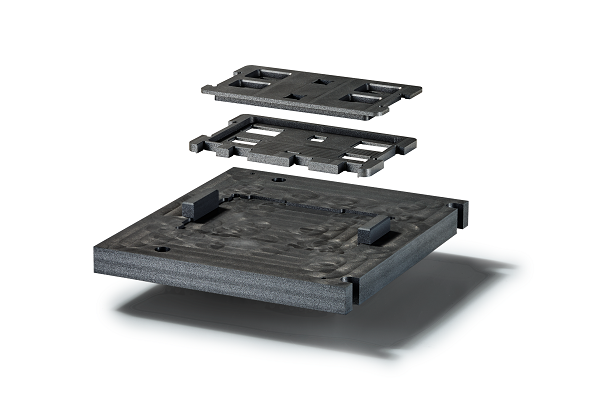

AMX Automatrix srl

AMX approached the power electronics field, identifying the technical gaps and the future market trend. Then after years of study research, we developed and patented a range of die-attach related equipment, now known all over the world. AMX worldwide patented a unique sintering tool for its sintering press, the so called "Micro-Punch" able to press individually and with a dedicated pressure every single component on the substrate (thermistor, IGBT, mosfet, die, chip…)

Ag / Cu Sintering

Pressure sintering is a die attach heat treatment process applied to a powdered material in order to give it higher strength, integrity and conductivity. Pressure sintering is now considered the most reliable technology for power electronics packaging.

- ●Highest melting temperature >400 °C

- ●Best thermal conductivity coefficient >150 W/(m K)

- ●Best electrical conductivity coefficient

SAT

The AMX X-SAM is a new system designed for quality control in power electronics industries. A non-destructive inspection able to simplify the manufacturing process. A fully automatic inline solution customized on the client’s design and requirements.

X-Sinter P50 Series

- ●Manual system

- ●Suitable for R&D, prototyping and Quality inspection

X-Sinter P100 Series

- ●AMX-patented “Micro-punch” applied

- ●Suitable for R&D and low production

X-Sinter P200X Series

- ●AMX-patented “Micro-punch” applied

- ●P200XM : Semi-auto system

- ●P200 : Fully automated

- ●Control the atmosphere (Vacuum, N2, forming gas etc.)

Inline X-SAM

- ●AMX-patented “Water Split System” applied

- ●Fully automated system

- ●Sensitive surfaces are protected from water

Schunk Sonosystems GmbH

Schunk Sonosystems is a globally leading specialist in the field of ultrasonic metal welding.

When it comes to the electrical "nervous system" of a vehicle, the wiring harness, Schunk Sonosystems has ensured millions of perfect connections around the world.

Ultrasonic welding

Ultrasonic welding is a future-oriented process that joins metals together using ultrasound.

In addition to copper and aluminum connections, metal and glass can be joined together. a permanent, solid and metallurgically pure joint with outstanding physical properties is created without thermally stressing the components. The range of products spans from welding systems for the wiring harness industry to complex special systems for the solar, electronics and semiconductor industries, as well as for the manufacture of batteries.

FX20-L-T

- ●Semi-automated system

- ●Suitable for Power electronics (e.g. IGBT modules) or Cell contacting system (Battery applications)

DS20-S-Plus

- ●Manually operated ultrasonic welding machine

- ●Suitable for laboratories, prototyping and small production of Power electronics or special applications

FX20-2L-R

- ●Fully automated system

- ●Suitable for Power electronics (e.g. IGBT modules) or Cell contacting system (Battery applications)

- Solder Preform

- Soldering Paste

- Sintering Paste

- Guide Jig

- Thermal Materials

Solder Preform (PFARR Stanztechnik GmbH)

Ever since the establishment of PFARR Stanztechnik in 1982, we have been committed to a high level of reliable quality coupled to flexibility and maximum reliability. PFARR Stanztechnik produces products for diverse industrial applications including electronics, microelectronic and automotive sectors. PFARR provides top-quality tooling, enabling us to meet and exceed specific customer needs with maximum flexibility and efficiency.

High purify

soft solders

PFDS400®

High purity

braze

Landal-Seal®

WireGaurd®

High Purify soft solders

Our soft solders are characterised by their excellent solderability. Our general range covers the following solder compositions (melting points from 115°C – 450 °C).

| Lead-Free solders | Lead-bearing solders |

|---|---|

| Sn-Basis | Pb-based |

| Bi-based | SnPb |

| In-based |

PFDS400®

Preform based diffusion soldering technology for high temperature applications: above 400 °C

Using conventional soldering processes with short dwell maximum peak temperatures of 250 °C, these new composite materials produce complete intermetallic phases (IMPs) in the Lead-free solder junctions without pressure or reheating. The overall thickness ranges from 50 μm to 300 μm.

High purity braze

Our braze materials are alloyed under vacuum, free from oxides, resulting in excellent wettability.

| Alloy composition |

|---|

| Ag-based |

| Cu-based |

| Al-based |

| Au-based |

Landal-Seal®

With a eutectic melting point of 214 °C, Landal-Seal® is ideal for a wide range of soldering applications. The revolutionary composition imparts the material with unusual physical and metallurgical properties: its stability to temperature cycling is around three times higher than that of conventional SnAgCu [SAC] solders.

WireGaurd®

In these preforms fully integrated wires of high melting point control the bondline during soldering as they do not change their state. 95% of initial preform thickness can be controlled through the spacer wires.

Dangyang SOLTEC

Since its establishment, Danyang Soltec has been supplying soldering products with high production capacity and stable quality to global customers at home and abroad. We develop high-performance soldering materials optimized for electronic products such as automobiles and smartphones as well as semiconductors that require particularly high quality. Recently, we have launched specialized solder pastes and fluxes for Mini LEDs and Micro LEDs, contributing to the opening of the next generation display era.

DS-0201HZ

High Temp Solder Paste

- ●Composition: 5Sn 2.5Ag 92.5Pb

- ●Powder Size: 20 - 45㎛,

- ●Non-Cleaning Solder paste

- ●Suitable for high speeds printing

DS-0304LF 305

Water Soluble Solder Paste

- ●Composition: Sn 3.0Ag 0.5Cu (87 – 89 wt%)

- ●Powder Size: customizing (#4, #5, #6, #7)

- ●It is designed for application where water cleaning is used.

- ●Suitable for Laser soldering

DS-0303

Water-soluble Paste Flux

- ●VOC-free, Halide Zero

- ●It is designed for application where water cleaning is used.

- ●Suitable for Laser soldering

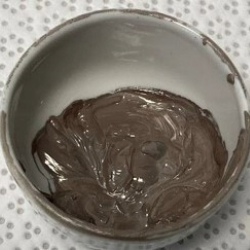

Nano-Join GmbH

Nano-Join GmbH is a young technology company based in Berlin with strong expertise on sintering materials with broad and flexible application possibilities. We provide several sinter pastes and offer customized materials ans services. The primary goals of our innovative sintering solutions are to make high-performance electronic components from the fields of optoelectronics, e-mobility and renewable energies more performant and efficient.

NJ One

Universal Ag Sintering Paste (pressureless)

- ●Storable at Room Temperature

- ●Ag(Silver) content: ~92%

- ●Shear strength: up to 80 Mpa

- ●Thermal Conductivity: > 250 W/mk

NJ Dispense

For dispensing, contactless printing (pressureless)

- ●No harden at Room Temperature

- ●Ag(Silver) content: ~92%

- ●Typical viscosity: 17 Pa·s ; 5 rpm

- ●Viscosity can adjusted if wanted.

NJ Force

Paste for sintering with pressure

- ●Pressure: > 1 Mpa

- ●Area: > 100 mm²

- ●Only One-step for complete module assembly

- ●One-step die- & substrate-attach

NJ Gold

Designed for gold and silver surfaces/finishes

- ●Storable at Room Temperature

- ●Ag(Silver) content: ~92%

- ●Typical viscosity: 10 Pa·s

- ●Shear Strength: up to 60 Mpa (pressureless on Au)

NJ Fusion

Cu-Ag Hybird Paste

- ●Metal content: 85% or more

- ●Cu content: 25% ~ 75%

- ●Cost reduction by >20% in comparison to Ag pastes

- ●Typical viscosity: 15 Pa·s ; 5 rpm

Schunk Carbon Technology GmbH

Schunk Carbon Technology is a global leader in the development, manufacture and application of carbon and graphite solutions. Like no other company, we combine innovative strength and exceptional service to offer a range of products and services that is unique in the market.

Aluminium Graphite

Solution for efficient heat dissipation

- ●Rapid heat transport

- ●Customized expansion behavior

- ●Lightweight solution

- ●Customer-specific designs

Latent Heat Carbon

Solution of short-term temperature spikes

- ●Combining the heat dissipation properties of Graphite with the heat storage capability of phase change materials

- ●Latent heat storage system

- ●Rapid response time due to graphite’s high thermal conductivity

- ●High thermal capacity

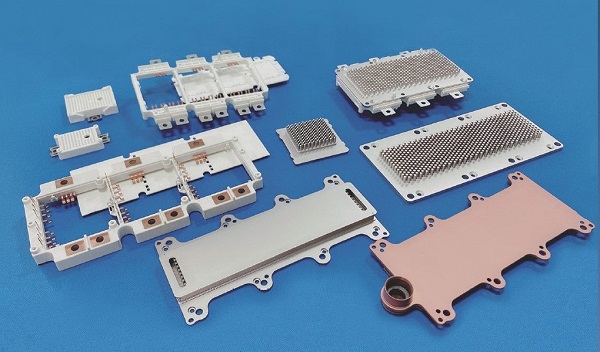

Jentech Precision Industrial Co., Ltd.

From prototype to high volume production, Jentech’s innovative manufacturing approach is guaranteed to bring a new level of competitiveness to your Global Supply Chain. Fully integrated Design, Tooling, Stamping, Molding, Plating and Assembly Service, enable Jentech to deliver superior value to our customers and minimize your total cost of ownership, while reducing cycle times.

AlSiC Thermal Spacer

For Double Side Cooling Module

- ●Composites combining SiC and Al

- ●Light weight, superior thermal conductivity

- ●Excellent thermal stability under high temperature (<400 ℃)

- ●Density: 2.95 – 3 g/cm³

- ●Low CTE: 8 ~ 10 ppm/K

- ●X, Y size: 3 – 15 mm / Z size: 1.0 – 3 mm

Base plate

Pin-Fin Base plate for direct liquid cooling

- ●Excellent cooling properties

- ●Improve thermal cycle performance

- ●Extend lifetime

- ●Various plating materials

| Full surface | Selective Variety coating |

|---|---|

| Ni-P Plating: 3-20 µm | Cu/Ni-P Plating: 3-20 µm |

| Ag Plating: 1.5-3 µm | |

| Au Plating: < 1 µm | |

| Cu spraying: 50-100 µm |

Lead Frame

- ●High precision stamped lead frame

- ●Multiple surface treatment option

- - Ag

- - Ni / Pd / Au

- - Selective Ni / Pd / Au

- - Ni / Selective Ag

IMS (Insulation Metal Substrate)

- ●Insulation layer: epoxy + ceramic

- ●Thermal conductivity : 8 – 12 W/mK

- ●CTE: 16 – 28 ppm/K

- ●Cu layer thickness: 0.5 – 3 mm

- ●High reliability and performance

Nanowired GmbH

NanoWired is The company with the metallic Velcro fastener. We research and develop substitution of solder, silver/copper sintering, TLPS, brazing, thermal connections, busbars. NanoWired creates an ideal electrical conductor without electrical resistance. The resulting is pure, monolithic copper joint. This outdates the waste of energy.

Joined at:

Room temperature

Low sintering temperature

Less needed energy in your production line leads to CO2 reduction.

NanoWiring

NanoWiring creates a metallic lawn on any surface. NanoWiring is a galvanic process similar to pad printing. Through the galvanic process, NanoWires can be deposited on nearly any material.

KlettWelding

In Kelttwelding, two substrates prepared with Nanowiring are joined by pressing them together at room temperature. The obtained bond has superior electrical and thermal characteristics.

KlettSintering

KlettSintering connects two substrates, only one of which has been prepared using NanoWiring. KlettSintering achieves significantly higher tensile and shear strengths than KlettWelding.

KlettGuleing

KlettGlueing enables the contacting of fragile components with an adhesive. KlettGlueing connects two substrates, only one substrate has Nanowiring structure. Adhesive is applied before low pressure and low temperature compression. Suitable for sensitive devices.